FH – horizontal combustion test

The FH test procedure is identical to the HB test, and categories FH1, FH2 and FH3 are distinguished in the classification.

The evaluation criteria include:

- Length of the burnt part of the sample;

- Burning rate.

Summary

Looking at the problem of flammability of plastic materials, it is worth noting that flammable and flame-retardant materials are used in switchboard cabinets. We deliberately do not use the words “non-combustible material” because each substance is flammable and its rate and method of ignition depend only on the prevailing environmental factors (burning time, temperature, oxygen content, etc.).

The least stringent testing method is horizontal HB, which is recommended according to PN-EN 60439-5 (until 2007, previous publications of this standard required FB testing). The HB rate has relatively few requirements for test samples, making it difficult to speak of flammable materials in this case.

A suitable criterion for assessing the flammability of materials is criterion V – vertical combustion test. The flame formed at the bottom of the sample heats its entire surface, which is a much more realistic reflection of the operation of the junction box in the event of an accident (when a source of high temperature occurs and then a fire). This situation can occur when the screws that connect the conductive elements are loosened or, e.g. under conditions of internal arc discharge that generates a significant amount of heat.

As mentioned earlier, one of the components of a thermoset material is the “extinguisher”, which determines not only the degree of flammability of the material, but also the price. It is also known that most business partners follow it as a key criterion in public procurement, while the technical value of the product is in the background. Finally, compliance with the minimum standards is limited, although all energy products must pass the V0 flammability test with positive results before entering the market (especially in German, French and Czech energy).

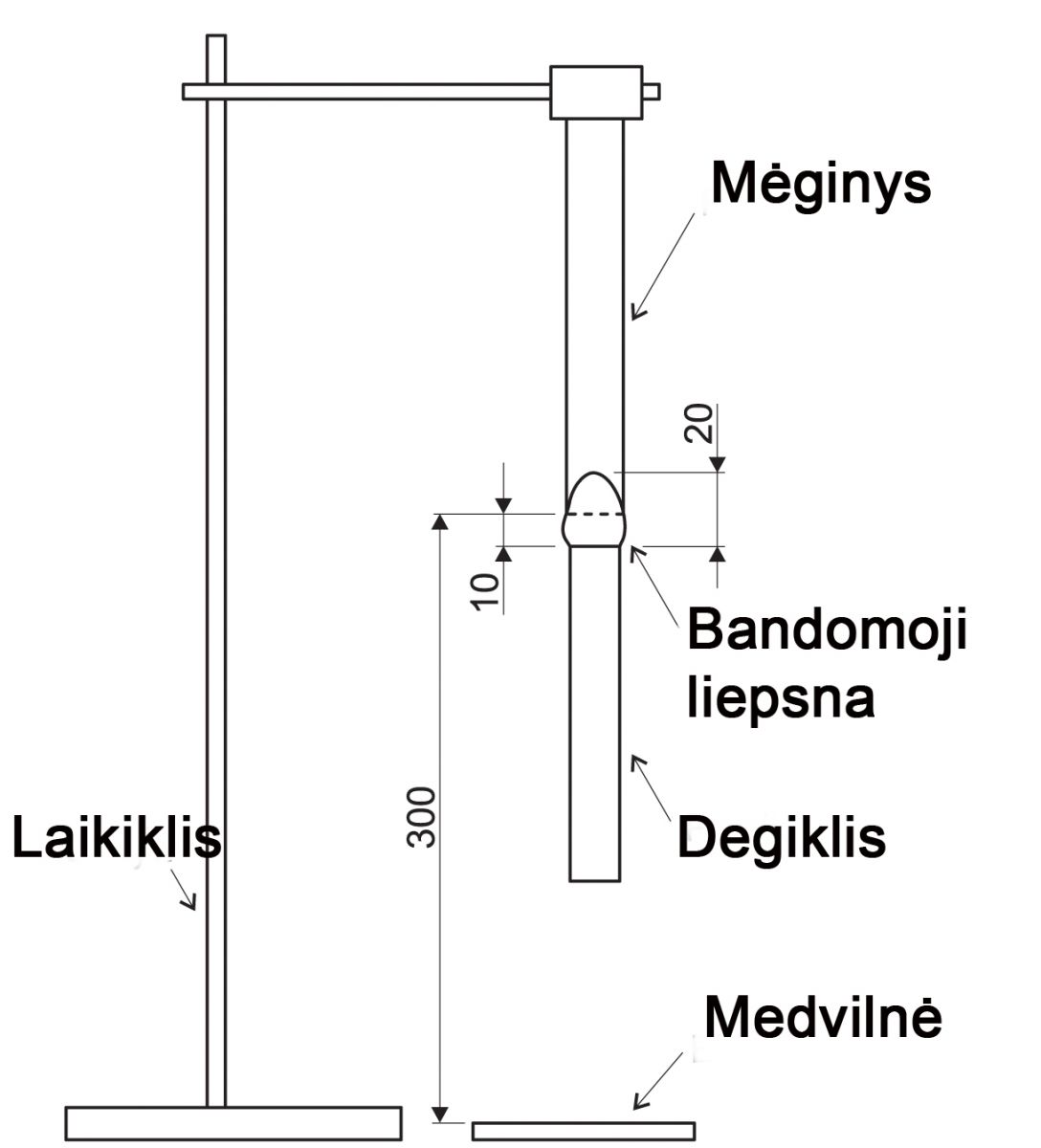

In 2009, EMITER carried out comparative tests of three competitive products available on the Polish market. As the laboratory of this company is not accredited, the determination of the flammability criterion was entrusted to an independent team of German researchers. The summary report states that none of the samples met the prerequisites for V0. Only the requirements of FH2 were met: sample No 1 – FH2 / 20 mm, sample No 2 – FH2 / 10 mm and sample No 3 – FH2 / 11 mm. Meanwhile, EMITER products are made of a material that meets the standard V0 – the strictest according to PN-EN 60695-11-10 in Poland. To maintain this, the flammability properties of the material are constantly monitored in the company’s laboratory. Below are videos that clearly demonstrate the quality of EMITER products and the innovative use of SMC material.